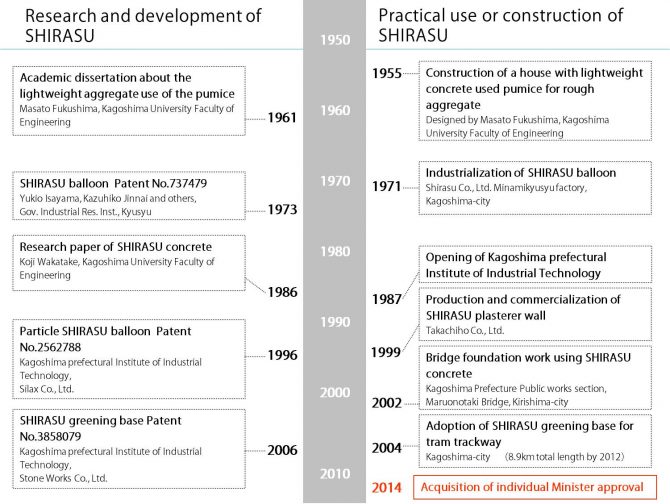

History of “SHIRASU” studies

Although “SHIRASU” had little or no value, our predecessors have not necessarily been sitting back with their arms folded.

Various researches on possibilities of utilization of “SHIRASU” have been carried out. It was used as a pavement subgrade material in the engineering field and also as land reclamation material. There has also been research in developing plaster material from “SHIRASU” but because of its qualities such as porosity, it was not authorized to be used as building material by the Architectural Building Codes.

Project Members

The idea of utilization of regional untapped materials such as “SHIRASU” in a concrete industry brought our team together to be established in 2012.

Our motive is to support the utilization of “Shirasu” resources, which is located in the Kagoshima prefecture and in parts of the neighboring prefectures, to develop fully recycled, environmentally friendly concrete from “SHIRASU” and bring this new material to the building industry.

Members : Yasuhiro Yamashita (Visiting Professor at Kyushu University and founder of Atelier Tekuto), Takafumi Noguchi (Professor at University of Tokyo, Researcher in fully recyclable concrete), Jun Sato (Associate Professor at University of Tokyo, Structural Engineer), Kazuro Higashi (Incorporated Company Principle Representative Director, “SHIRASU” Producer), Tsukasa Ito (Managing Director Tokyo SOC, “SHIRASU” concrete manufacturer).

With the cooperation of researchers at Kagoshima University, Kagoshima prefectural research institution, “SHIRASU” manufacturers, structural engineers and the concrete factory the project thus begun.

Obstacles to the Use in Architecture

Obstacles to the Use in Architecture

Four obstacles to construction: Material development and management.

Through the investigation of the project team for using “SHIRASU” in architecture became very clear. To tackle these obstacles each of the members performed their part in a highly professional manner to seek out the appropriate solutions.

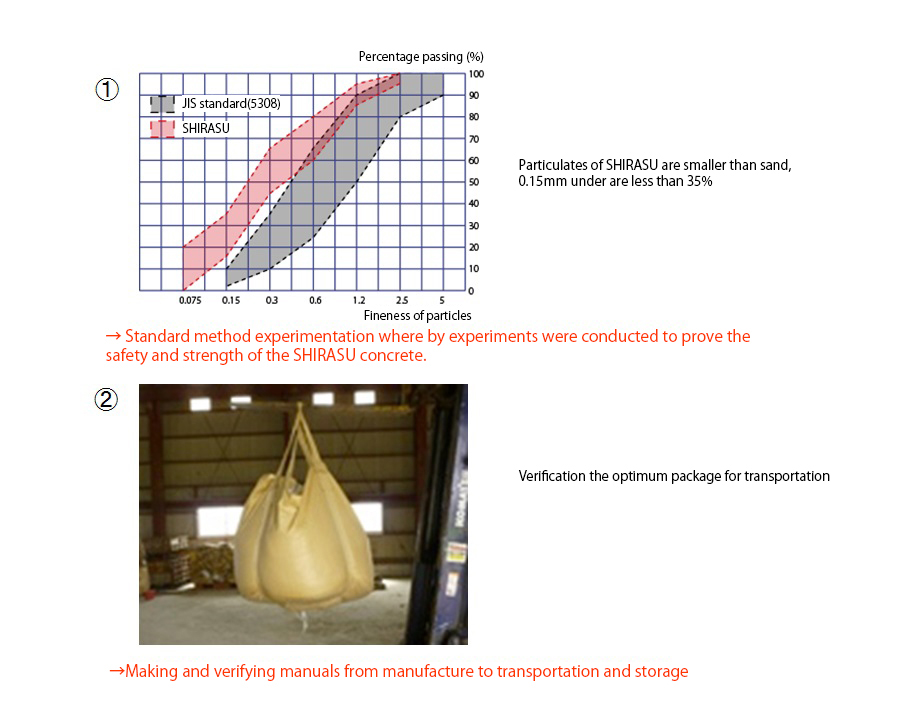

Obstacle 1. To meet the Architectural Building Codes.

The highest constrain in using “SHIRASU” in the fields of Architecture was conformity to the Architectural Building Codes.

The pyroclastic ashes originate in the volcanos and is a totally natural material and because of the fineness of its grains which is lighter than the sand as represented in the JIS standard, and having too much moisture prohibits its use in architecture.

Various experiments were conducted with “SHIRASU” added concrete on its strength. As a result, we found if we limit the use of “SHIRASU” to one building per special Individual Ministry of Construction Approval. Then we would win approval for the use of “SHIRASU” in architecture.

Obstacle 2. Quality control of “Shirasu”

Acquisition of an Individual Ministry of Construction Approval for “SHIRASU” concrete can be guaranteed only by the thoroughness in the quality control of “SHIRASU” , to the extent where the natural hence variable qualities of “SHIRASU” was controlled to a high level where it could be called an industrial material. Therefore, “Principle”, the “SHIRASU” manufacturing company devised a quality controlling method and compiled a manufacturing manual.

Obstacles to the Use in Architecture

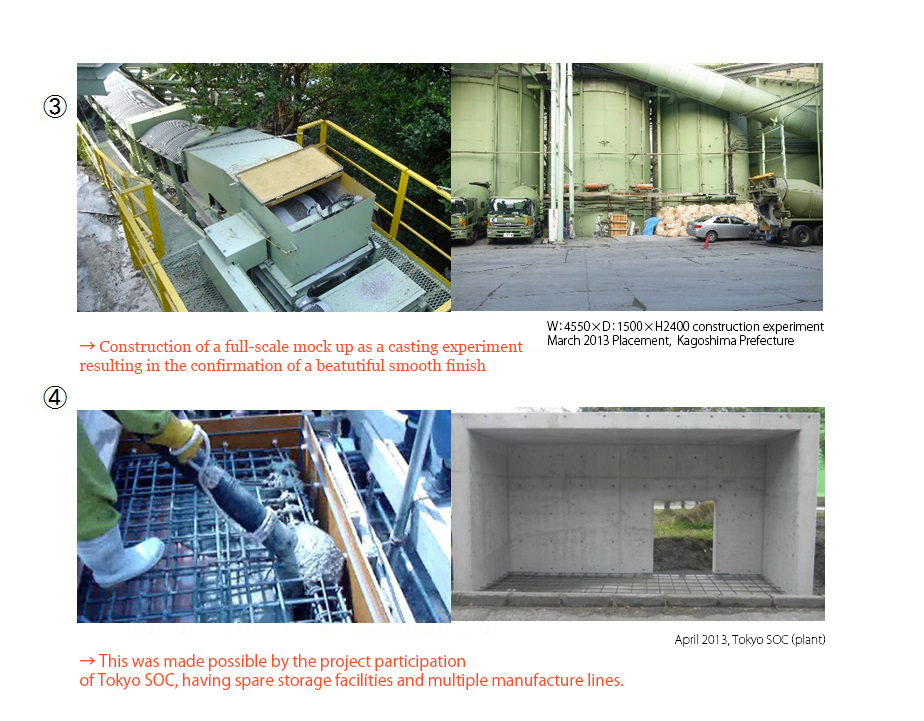

Obstacle 3. Plant that can produce the concrete.

Our aim was not only to document our research about using “SHIRASU” concrete but to actually use this material in a building. Even if the development of this material is possible, if there is no factory that will manufacture it, it cannot be used on the actual construction site.

So we had to search for a factory that could allocate a manufacturing line exclusively to “SHIRASU”. This was made possible by the participation of Tokyo SOC, having ample storage facilities and multiple manufacturing lines.

Obstacle 4. Checking the workability of the material on site.

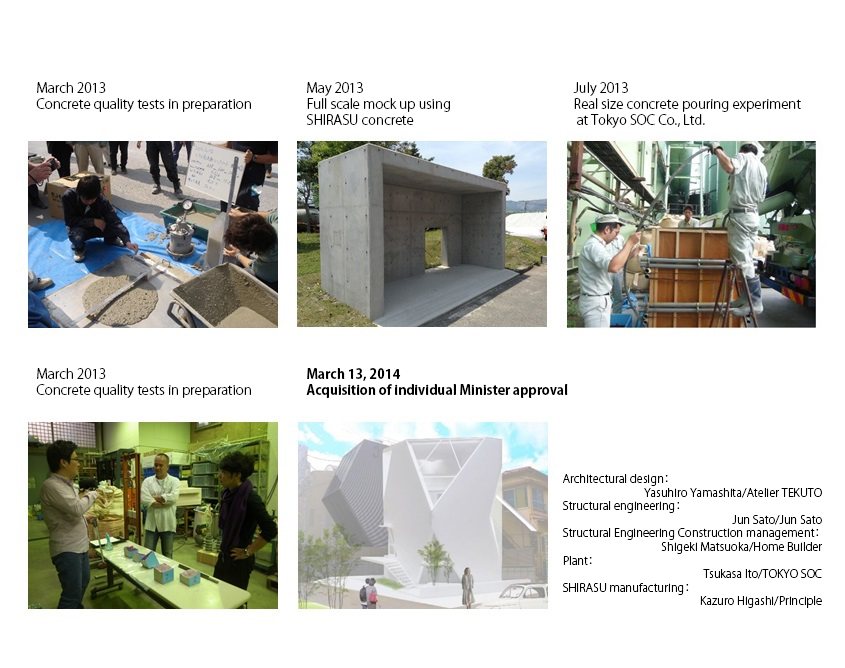

An architectural building is much smaller compared to civil engineering structures in which “SHIRASU” concrete had been used in the past. Good results and data obtained in the lab or the factory under optimized conditions does not necessarily mean construction will be smooth on the site, where the factor of uncertainty is an unavoidable risk. In order to extract in advance the element that is likely to pose a problem and to prepare solutions, a full-scale construction experiment was conducted. Construction of a full-scale mock up as a casting experiment resulted in the confirmation of a beautiful smooth finish.

Acquisition of Minister Approval for the Individual Project

Acquisition of Minister Approval for the Individual Project

The task of bringing “SHIRASU” to the manufacturing process and to start using it as a building material was not an easy one. We needed to undergo verification of all aspects of “SHIRASU” concrete. Form different physical properties of “SHIRASU” , such as neutralization examination, test of durability and examination of the different mixtures of proportions of ingredients in order to find the optimum solution.

Along with laboratory tests of material samples we constructed full-scale mock up in order to have real size concrete pouring experiment, durability check and to study material performance throughout the four seasons of the year. From the project team launch in 2012 through nearly two years of development experiments, finally in March 2014, we were able to acquire the “individual ministerial approval» to build one house using “SHIRASU” concrete.

Characteristics of Environmentally Conscious “SHIRASU” Concrete

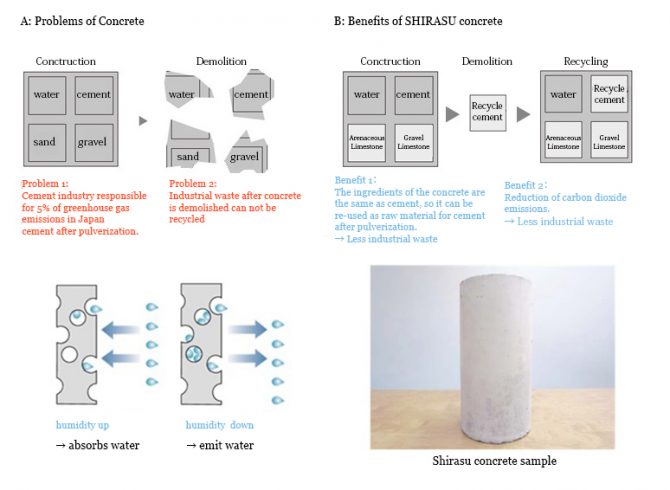

1. Contribution to the preservation of natural resources.

・60% to 70% of sand in concrete, which is becoming a scarce resource, can be replaced by “SHIRASU”.

2. Environmentally friendly.

・The concrete becomes completely recyclable as a cement raw material at the time of demolition.

・Calcination energy [of the cement] and CO2 emission can be reduced.

3. Strength and durability

・Strength and durability that increases to grow over a long period of time because of the pozzolanic reaction of “SHIRASU”, resistant to sulfuric acid and salt-damage

・Also its density, which comes from the fine granularity of “SHIRASU”, protects the concrete from neutralization

4. Smooth surface, humidity controlling qualities

・Smooth texture allows to have exposed concrete as fine finish.

・”Shirasu” also contains micro closed-cells which give the concrete humidity control and deodorizing qualities.