Social Background

Yamashita is intrigued by the way materials such as concrete, steel and glass has had such an impact on the way our physical world and landscape was formed in the 20th century. This has led to his drive to show, in his architecture, how materials and its structures play a significant role in forming our physical world.

In particular, he is strongly attracted to masonry structure. The reasons for this can be summarised in the following three points.

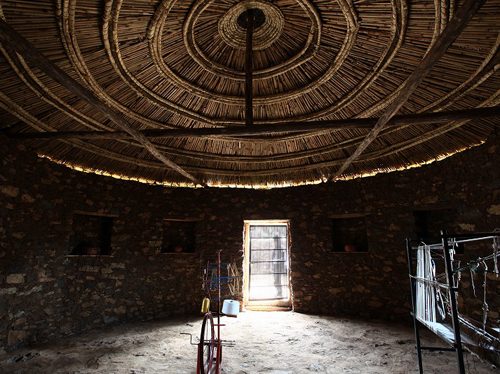

1. It is the major origin in Western architecture and a fundamental, historical structural system in architecture that has been used since ancient times.

2. Material, Structure and Finish are unified and the one material expresses all aspects of architecture.

3. Although each element is a small entity, they unite to form an integral piece of architecture.

Yamashita’s interests have spread to glass as a fragile material that may exert its strength depending on how it is applied and combined with other materials. The thinness of a flat pane of glass deters its use as a structural element, but a glass block has sufficient thickness to become structure. The void in the glass block filled with air also gives it an insulating effect allowing for a thermal environment usage.

This section introduces initiatives to achieve a ‘glass block masonry structure’. It springs out of a desire to critically question architectural norms and leave a positive trace in the long history of architecture.

With this motive a huge effort was made to show how glass can become a structural, thermal, environmental device, transmitting an abundance of light at the same time.

1.The weak join hands to demonstrate their strength

Crystal Brick’ (completed 2004)

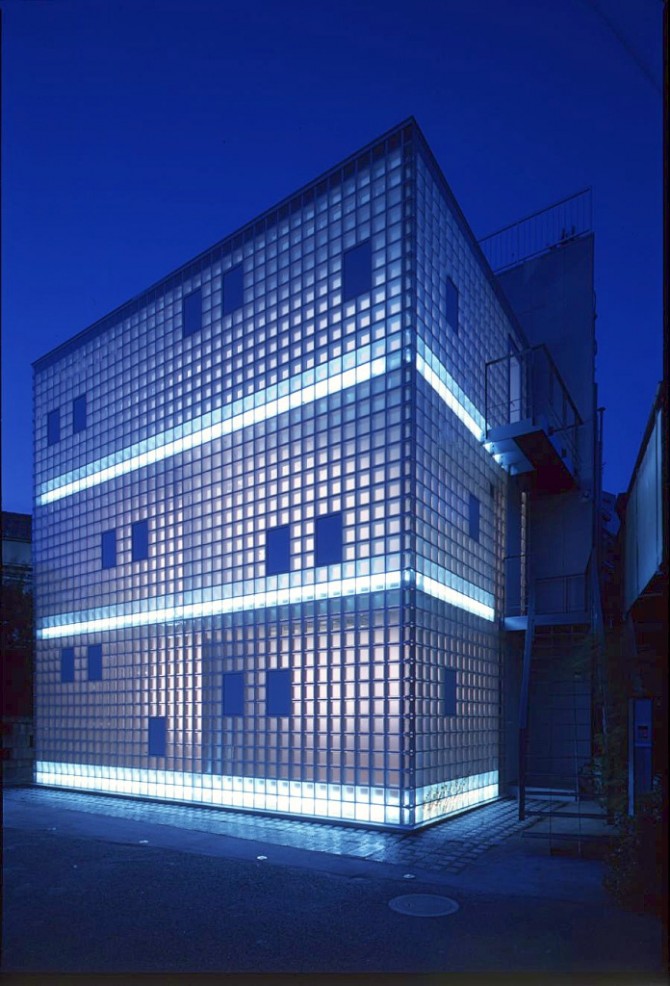

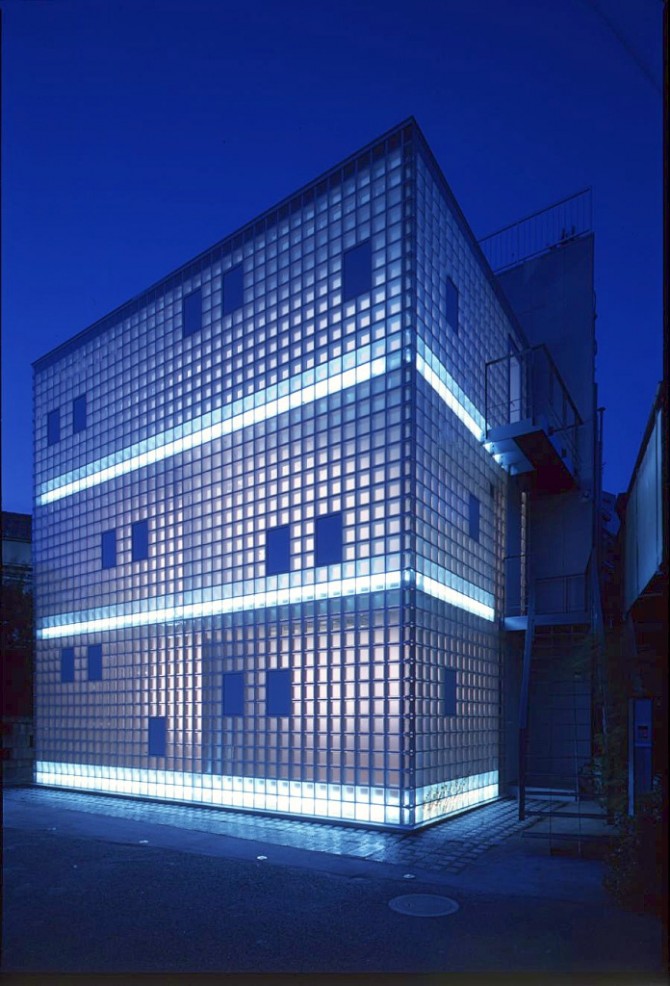

A glowing structure

This house in Bunkyo Ward, Tokyo, is a three storey, two-family home for a parent couple, a young couple and their two children. The client wanted the first floor to be the home of the parents and the second and third floors to be the homes of the younger couple, each with bright living spaces filled with light or a ‘sparkle’ or a “shimmer”, as the client put it, words that sprang out of the minerals that the client collects as a hobby. These initial discussions led us to focus on the use of glass blocks.

From the early stages of the project, experiments were conducted by architects, structural engineers, glass block manufacturers and researchers from universities. The aim was finding out a way in which glass blocks could be used as a structural element for the exterior walls.

Until then, there had been no examples, let alone attempts of glass blocks being used as structural element. Even the manufacturers themselves were hesitant. Yamashita on the other hand as always, was neither hesitant nor over-optimistic. His approach, when confronted with the unknown, is to carry out experiments, collect data and make judgements after accumulating enough information. After extensive experimentation, it became clear that the compressive strength of glass blocks could be used in a structural manner.

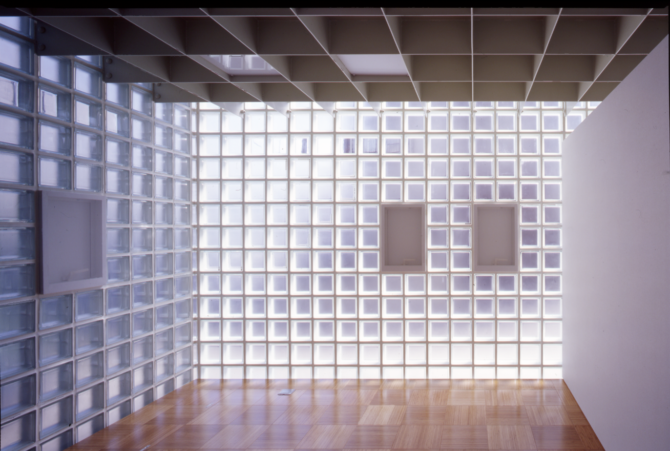

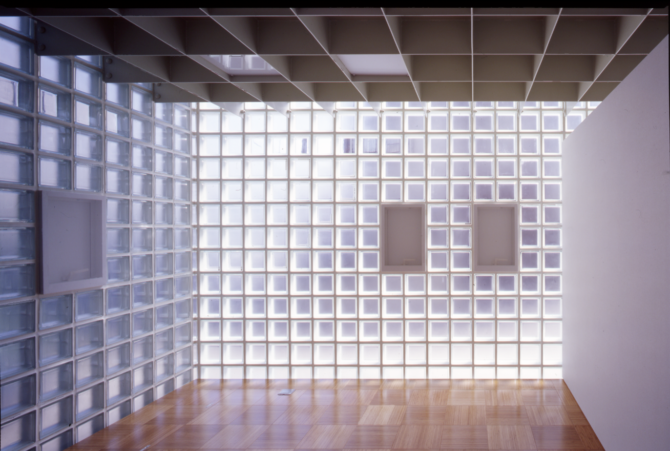

A small buffer material

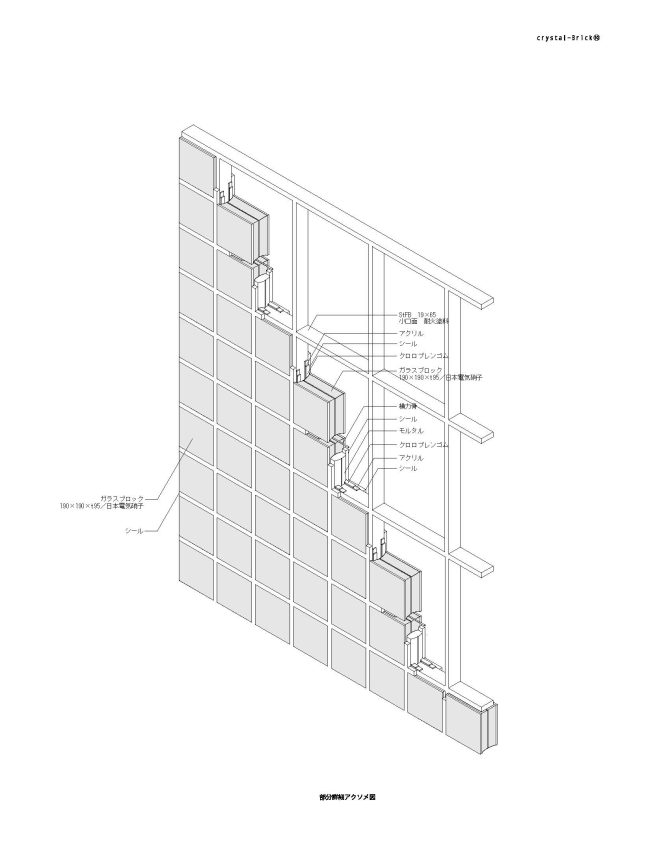

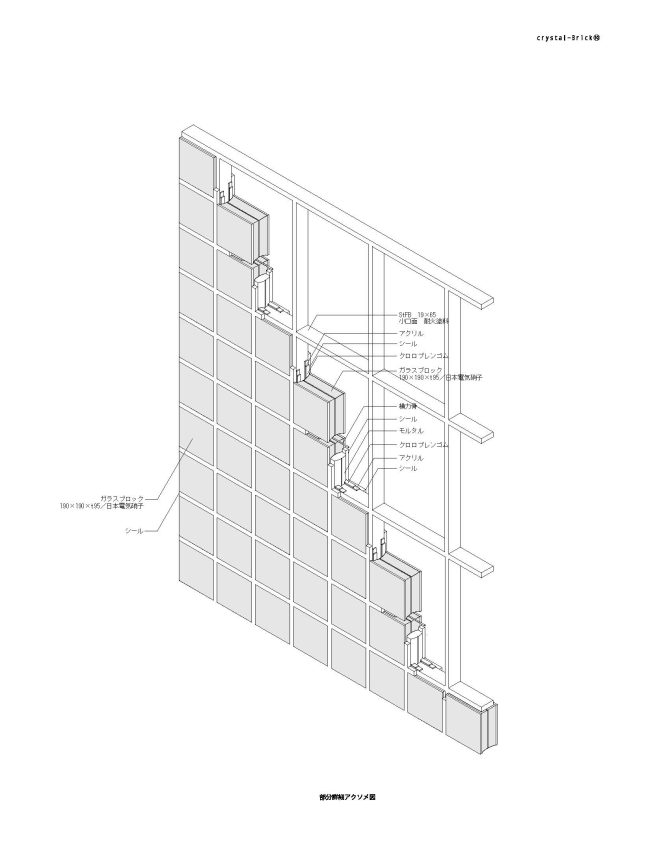

As a structural element, a very thin steel flat bar lattice is constructed. The structure is so thin that by itself, the structural deformation of the lattice would be unacceptable as a building. After the glass blocks are laid into the lattice, the compressive qualities of the glass blocks stabilize the architecture. When completed, the steel flat bars are no longer visible and the whole building appears to have been made entirely of glass blocks. As a result, a beautiful shimmering living space is created and the allocation of transparent and semi-transparent glass blocks adds to its beauty.

Thin steel plates called steel flat bars: 19 x 65 mm are assembled in a 400mm x 600mm grid. By itself, steel flat bars are too weak as a structure. When six glass blocks of 190 x 190 x 95 mm are inserted into each 400mm x 600mm grid, the glass blocks bear the horizontal forces, while the steel flat bars are able to carry the compressive forces in a stable manner.

The key to this system was actually the small buffer element between the glass blocks and the steel.

To prevent direct contact between the glass blocks and the steel members, a thin cushion material was inserted in between the two materials. This buffer had to be stiff enough to transmit the relevant structural forces but at the same time be soft enough to protect the glass blocks from breakage. After extensive trials and errors using different materials, the solution was nothing special, just a 1 mm thick chloroprene rubber sheet and a 2 mm thick acrylic sheet combined.

The three elements of the structure, a steel flat bar, glass blocks and cushioning material are each very weak and fragile on their own, but the combination of these three elements allowed for a sturdy structural external wall that let light to pass through with no visible frames. The structure was patented for its ingenuity.

The spatial qualities of glass blocks

The completed glass block exterior looks like a soft luminescent object, shining softly at night. Inside, by using transparent and semi-transparent glass blocks in different places, we were able to create a living space with a soft ‘mistily’ shimmering light. The glass blocks support a steel-framed lattice ceiling, creating a space that seems to defy gravity and one’s sense of normal perception.

Pierre Chareau’s Glass House and Renzo Piano’s Maison Hermès are considered masterpieces of glass block architecture, but we are humbly proud to say we have achieved an apex in glass block architecture with a totally different approach from these examples.

2.Steel + glass block + ALC: three-way series

Twin-Bricks (completed 2008), Crystal Bricks II (completed 2011).

Homogeneous treatment of the transparent, the semi-transparent and the opaque

Pioneering the use of glass block structures with ‘Crystal Bricks’, we were also dealing with a design problem of how much light passes through these walls. We did so using transparent and semi-transparent glass blocks. The following projects are examples in which we incorporated opaque elements for further control of light while keeping in line with the structural cept of treating the elements equally. The projects are: ‘Twin-Bricks’, completed in 2008, and ‘Crystal Bricks II’, completed in 2011.

In both buildings, we decided to use ALC or Autoclaved Lightweight Concrete as the opaque element. ALC is usually used for external walls that is not a structural component, but just a barrier between the inside and the outside, similar to the original use of glass blocks. The choice of ALC came from a gut feeling which can only be based on many years of experience.

In the course of experimentation conducted in cooperation with universities and manufacturers, we discovered that glass blocks and ALC have almost equal compressive strength and tenacity. Although they are different materials but have the same structural qualities, affords the interchanging of glass blocks and ALC with no special considerations, assuring the stability and balance of forces.

The surfaces that let in light and external scenery (transparent glass blocks) and the surfaces that block views (ALC panels) are interchangeable and can be freely selected, so to speak, and they comprise a ‘flexible structure’. Cost savings are also achieved by replacing some of the glass blocks with ALC panels.

3.Cost reduction by integrating steel construction + glass block panel construction1

White ladybirds’ (completed 2008).

Flickering light from glass blocks.

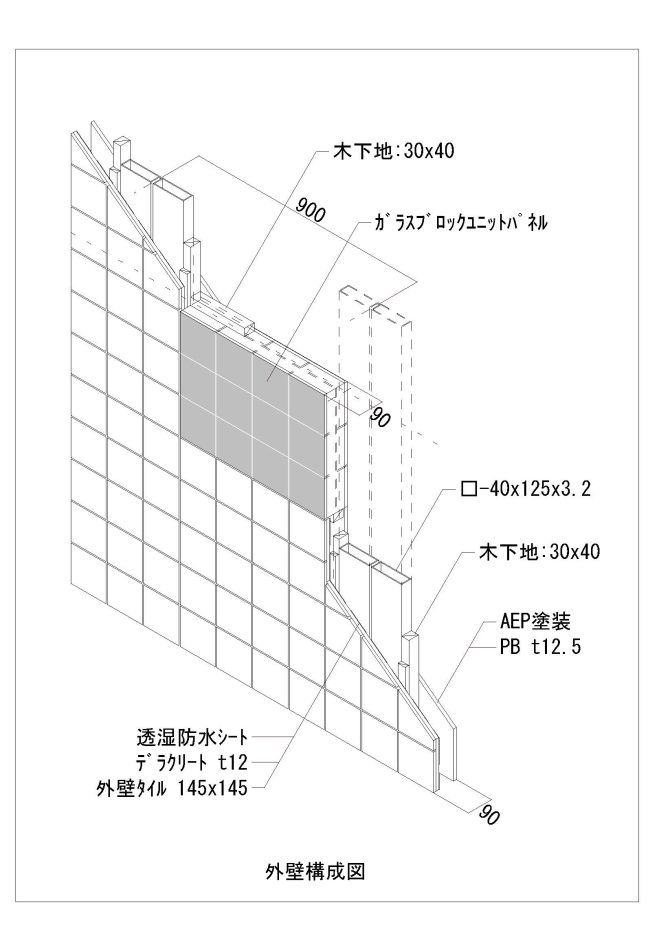

As a variation of the challenges concerning glass blocks, we present a construction method using ready-made glass block unit panels. This was a project that started with requests from JEOL Glass company to utilize their special glass block panels.

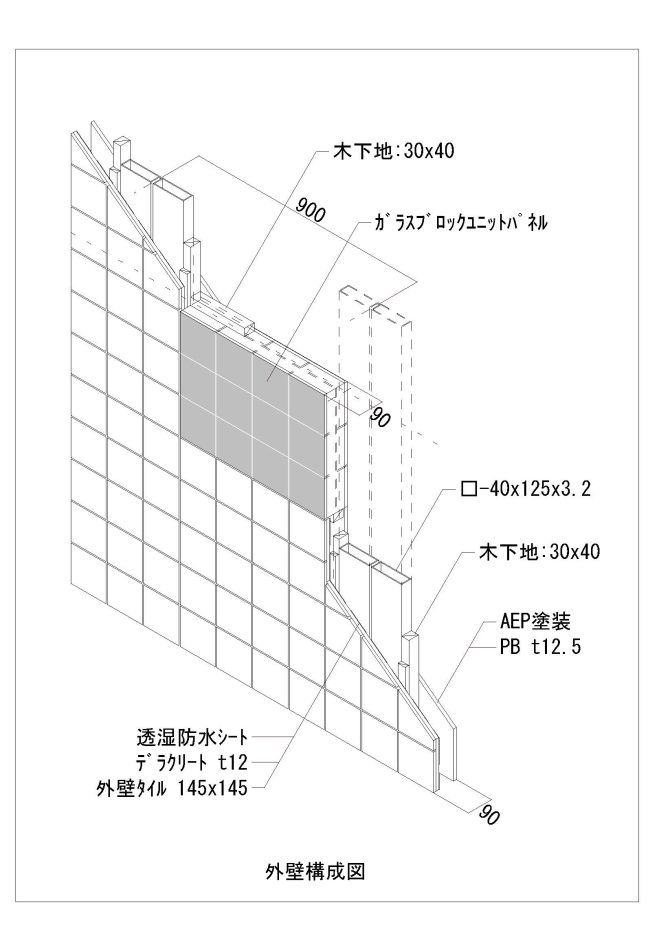

The external walls cladded with tiles are made at a thickness of 95mm, so as to be aligned to the thickness of the 95 mm glass block. The reason for doing this was to integrate the tiles and the glass blocks in a continuous surface.

In order to accommodate the multi-inclined wall facade, the joints of the panels were made of special prefabricated steel panels comprised of 40 mm x 125 mm steel pipes that allow the angle of the panels to be changed freely. The external wall tiles are custom-made 145 x 145 mm tiles to match the glass block and the joints between the glass block and tiles.

From these innovations, the boundary between the wall and the opening is blurred, and the glass block and tiles appear to have the same texture during the day, while at night the glass block emerge as patches of light, somewhat similar to the appearance of a white ladybird.

“Resale value” -the key word of the project

“Resale value” was the keyword discussed with the client in the early stages of design, taking into account that Japan’s population had been declining since its peak in 2006, the site’s location, a place which may eventually be redeveloped, and the possibility of resale in five to ten years’ time. So we excuted a design with a capacity for the building to be converted into uses other than just residential. Another related request from this viewpoint was that the exterior tiles should keep its original beauty reducing its deterioration coming from ageing. So the tiles were custom ordered 145mm square tiles with a special Microguard finish, manufactured with the cooperation of INAX company.