Social Background

Many of the buildings, by which we are surrounded, are mostly made of concrete. In fact, the history of concrete as a building material goes back a long time. It is known that the prototype of modern concrete was used for the construction of the Pantheon during the period of the Roman Empire. This highly durable material was called roman concrete and its main ingredient was volcanic ashes.

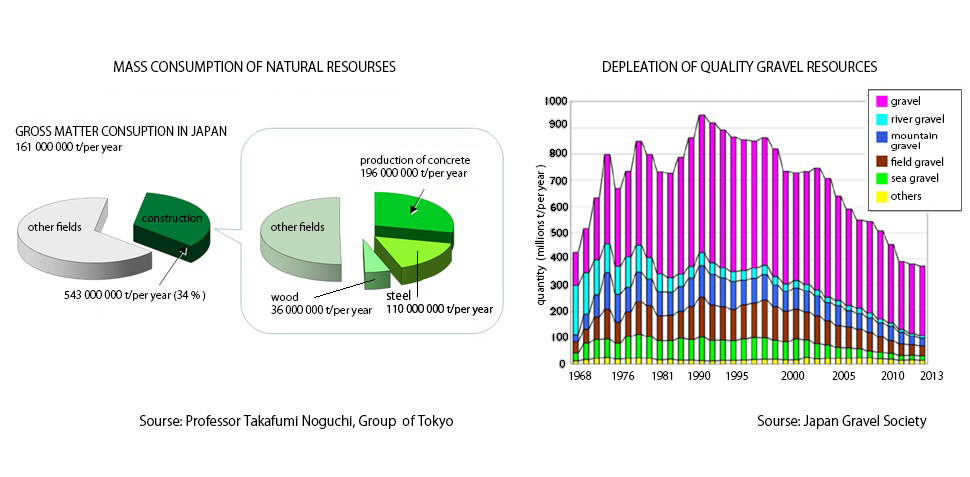

Contemporary concrete consists of cement, sand, gravel and water. Although it has an artificial appearance, concrete is made from natural resources which are quite limited. It is up to us, living as we do in the 21st century, to have the wisdom of using limited resources more efficiently.

Current Status of Concrete – 1

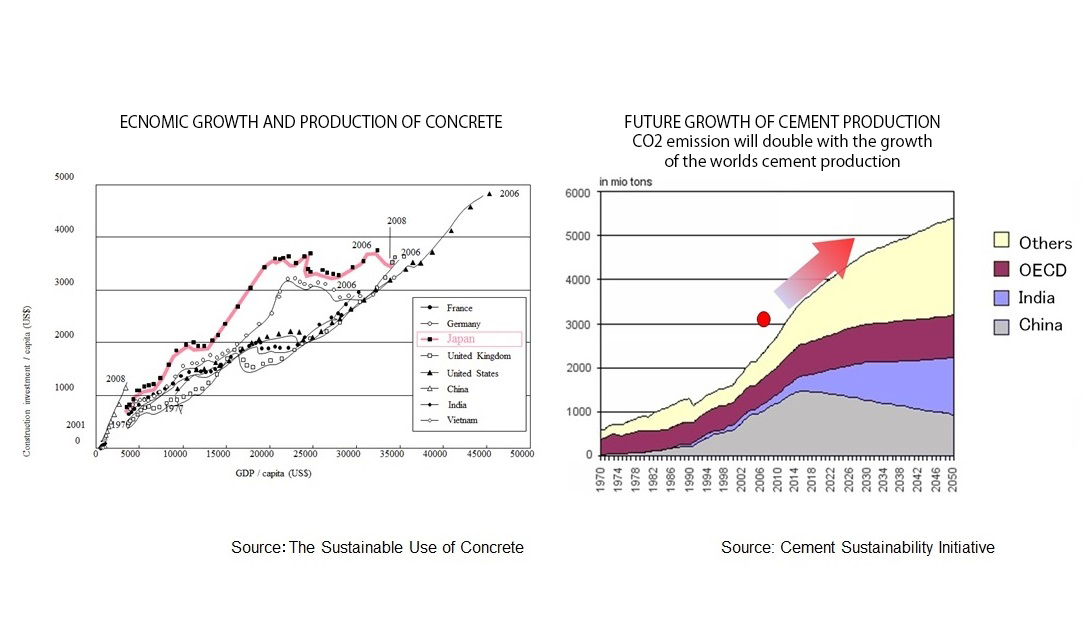

In the 20th century, the production of concrete which was the driving force for the building industry, made a constant increase in synchronicity with economic growth.

It is expected that the production of cement, being the main ingredient of concrete, will continue to increase. It is assumed that the consumption will be doubled by 2050 compared to the turn of the century. Additionally, cement is produced by heating natural limestone with other materials through a process known as calcination. In order to calcine at the high temperature of 1450 °C, a lot of heat energy is required that results in vast CO2 emission.

Current Status of Concrete – 2

The aggregate for concrete are gravel and sand. Both are natural resources. Up until the economic boom, these materials were extracted from dry river beds or mountains resulting in drainage of good resources. Instead manufactures started to use sand from the seas. This results not only in the rusting of the reinforcement bars in concrete, but also contains many chlorides that originate from the sea water, which causes a general deterioration of quality of the concrete. Moreover, the extraction of beach sand is being regulated or banned by many local governments, because of the bad effects it has on the marine environment.

It is a matter of utmost urgency with in the concrete industry, clearly an industry that is indispensable to contemporary architecture, to search for alternative resource that could be utilized instead of sand and gravel. Also to change the formation of the recycling process of concrete, develop a more durable and multifunctional concrete.

This is how we came up with the idea for the practical use of volcanic “SHIRASU” as a fine aggregate.

What is “SHIRASU”?

“SHIRASU” is a general term for the deposit of pyroclastic flow of volcanic ash found in South of Kyushu. It covers almost half of the Kagoshima prefecture (4,600 km2) with an average thickness of 60m.

The amount of deposits are estimated to be 75 billion m3, enough to fill the Tokyo Dome 60 000 times. Since it is not suitable for agriculture due too high drainage and scarce nutritive substances, and corrosion and mudslides easily happen at the time of heavy rain, it is regarded as an unwelcome troublesome material.